Biomaterial [Part 1] – Experimenting with Bioplastics

This is a self-initiated project I did it together with my DIY BIO Hong Kong folks.

What is the motivation that drives me to do this project?

There are 3 reasons:

The plastic wastes problem. We lived in a city that produces many plastic wastes every day. News also reported that the wastes are not being recycled properly, and the waste can get to the ocean and take ages to degrade. Thus, I have a strong feeling to do something to help contribute to building a sustainable way and circular economy.

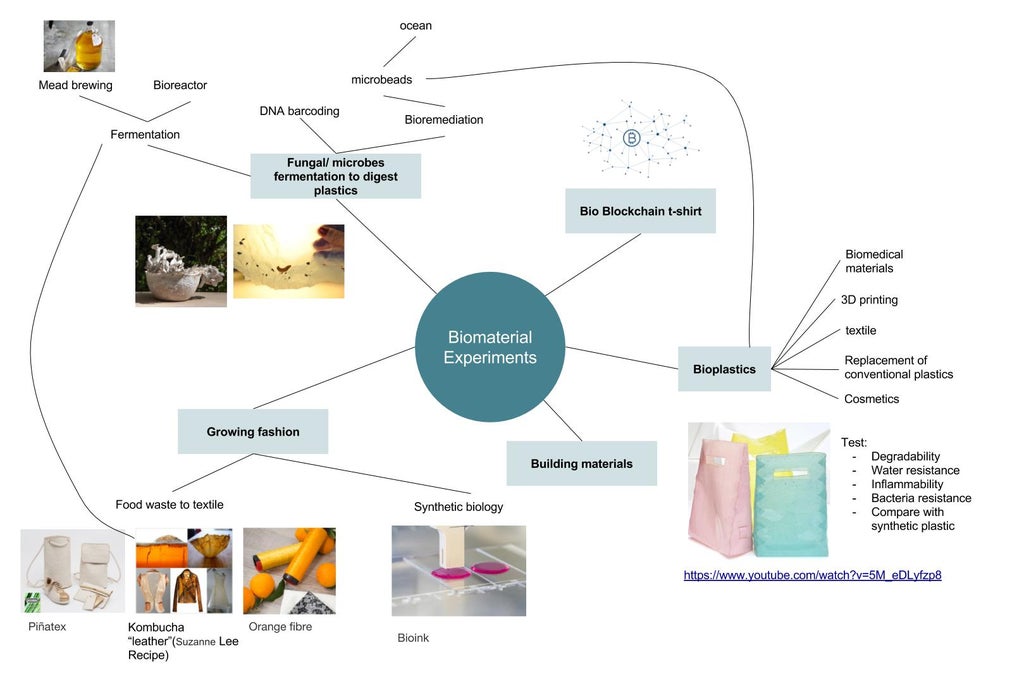

DIYBIO community project, combine our interests and specialties (you can see how we map out the project in the mind map below)

Personal reason: I was surprised to learn about the great pacific garbage patch (plastics soup) in the ocean when I attended an ecology lecture in university and as staff working in maker space, I see there are many wastages from packaging or scrapped laser cut and 3D printing materials every day. These reasons all make me want to design a material circular model that create less waste and develop new materials that are sustainable.

Watch this video, you will be shocked by how many plastics we discarded, and how it greatly affects our environment.

Experiment on Different Recipes

We tried several recipes (starch-based, gelatine-based, kombucha), while the method is quite universal. So I would like to introduce the method first.

Method

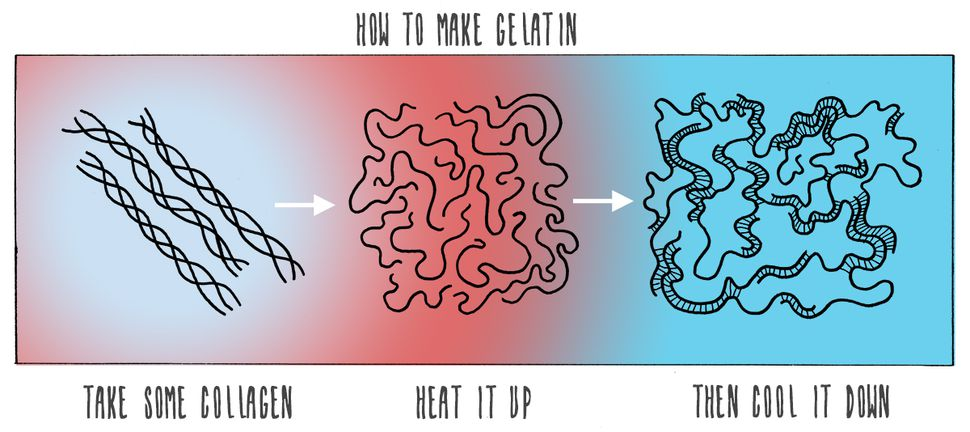

How does it work? In the heating process, carbohydrates form cross-links with adjacent chains to form a matrix. If you want to learn more, you can read this page.

Recipes

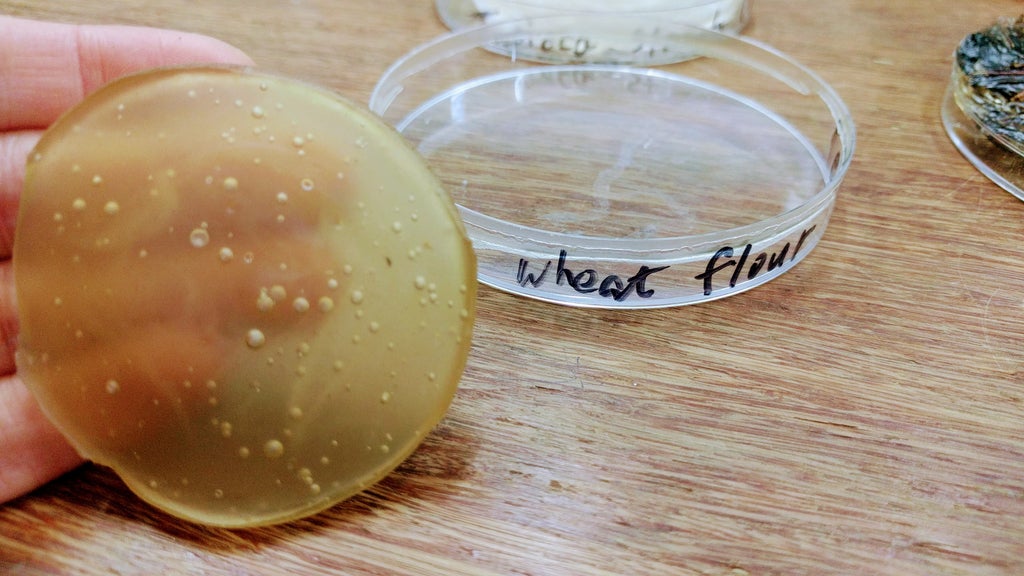

Starch-based

Recipe 1:

- 50mL Water

- 5mL Vinegar

- 5g Glycerol

- 6g Wheat Flour

Recipe 2:

- 50mL Water

- 5mL Vinegar

- 5g Glycerol

- 7.5g potato starch

Recipe 3:

- 50mL Water

- 5mL Vinegar

- 5g Glycerol

- 6g Tapioca starch

Recipe 4:

- 50mL Water

- 5mL Vinegar

- 5g Glycerol

- 7.5g sweet potato starch

Recipe 5:

- 50mL Beetroot juice

- 5mL Vinegar

- 5g Glycerol

- 7g potato starch

=== Reference: https://www.wikihow.com/Make-Bioplastic-Easily ===

Gelatin-based

Recipe:

- 240 mL cold water

- 48g Gelatin (you can get the jelly powder from the supermarket)

- 12g Glycerol (you can get it from the pharmacy)

— === Reference: Clara Davis (2017) Fabtextile === —

Kombucha

Recipe 1:

- 1.5L hot water

- Green tea leaves

- 150mL Vinegar

- 150g Sugar

Recipe 2:

- 750mL hot water

- Black tea leaves

- 75mL Vinegar

- 75g Sugar

Recipe 3:

- 750mL hot water

- Green tea leaves

- 75mL Vinegar

- 75g Sugar

You can put the bioplastic paste in a mold or simply pour it into a petri dish, spread it evenly, and let it dry. It usually takes 2-3 days to dry at 25C. In our case, we keep the lid open and incubate the bioplastic samples into an incubator under 25C for a week.

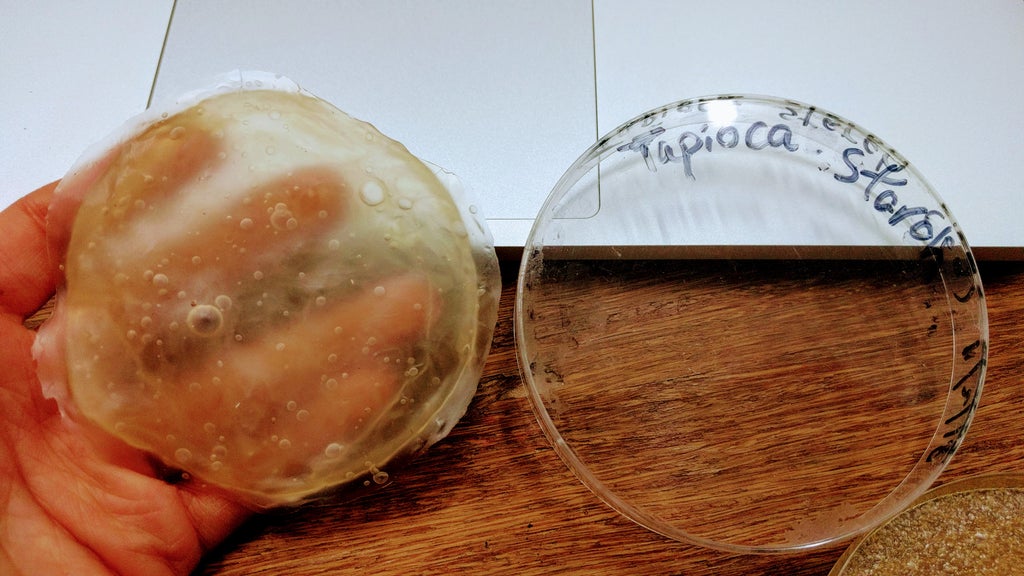

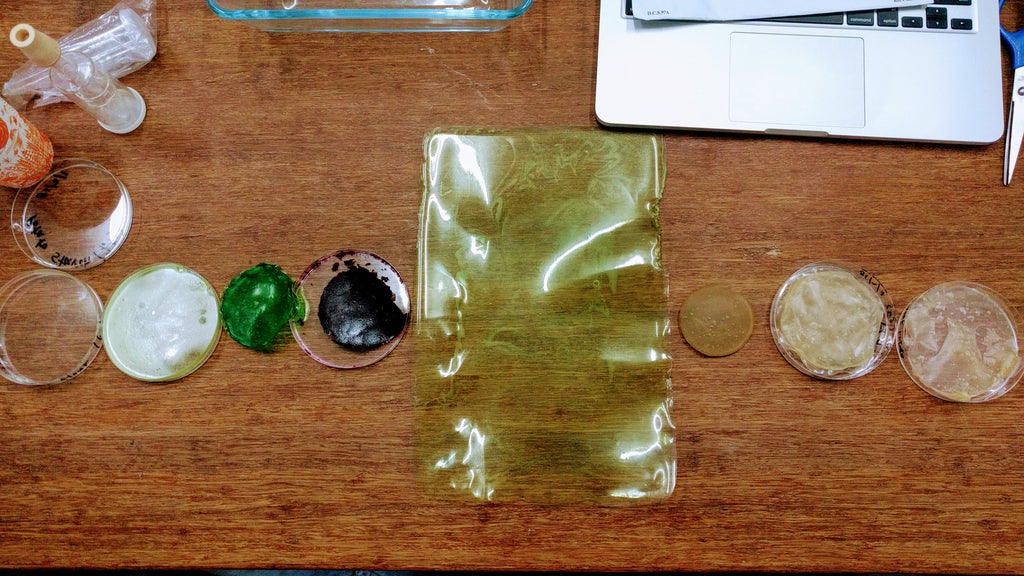

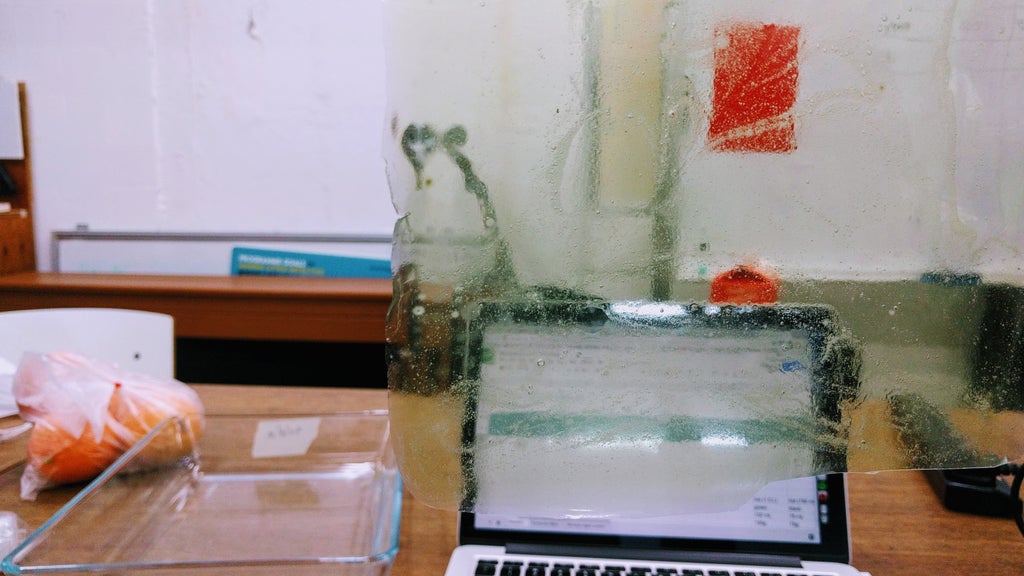

Making-of pictures:

Experiment Results

Starch-based bioplastic is quite viscous when heating it in the pan. It took around 3 days to dry. The resulting product is a very elastic piece.

Gelatin based bioplastic dries fast, easy to cast into a large sheet, and the final outcome is an elastic translucent elastic sheet. These properties make it a suitable material for laser cutting and sewing.

Our Kombucha experiment failed, mold grew on the surface. Maybe we need to sterilize the containers and the utensils properly with boiling water and vinegar. Another reason can be there were not enough bacteria stock in the mixture as we did not put a scoby to serve as a starter.

Property Test

We then conduct two property tests for the bioplastics.

1. Flammability test

The gelatin bioplastic sheet did not catch a big fire when in contacts with fire.

The Tapioca starch-based bioplastic burns in flames once it catches the fire.

Generally speaking, starch-based bioplastics are more flammable than gelatin-based bioplastics.

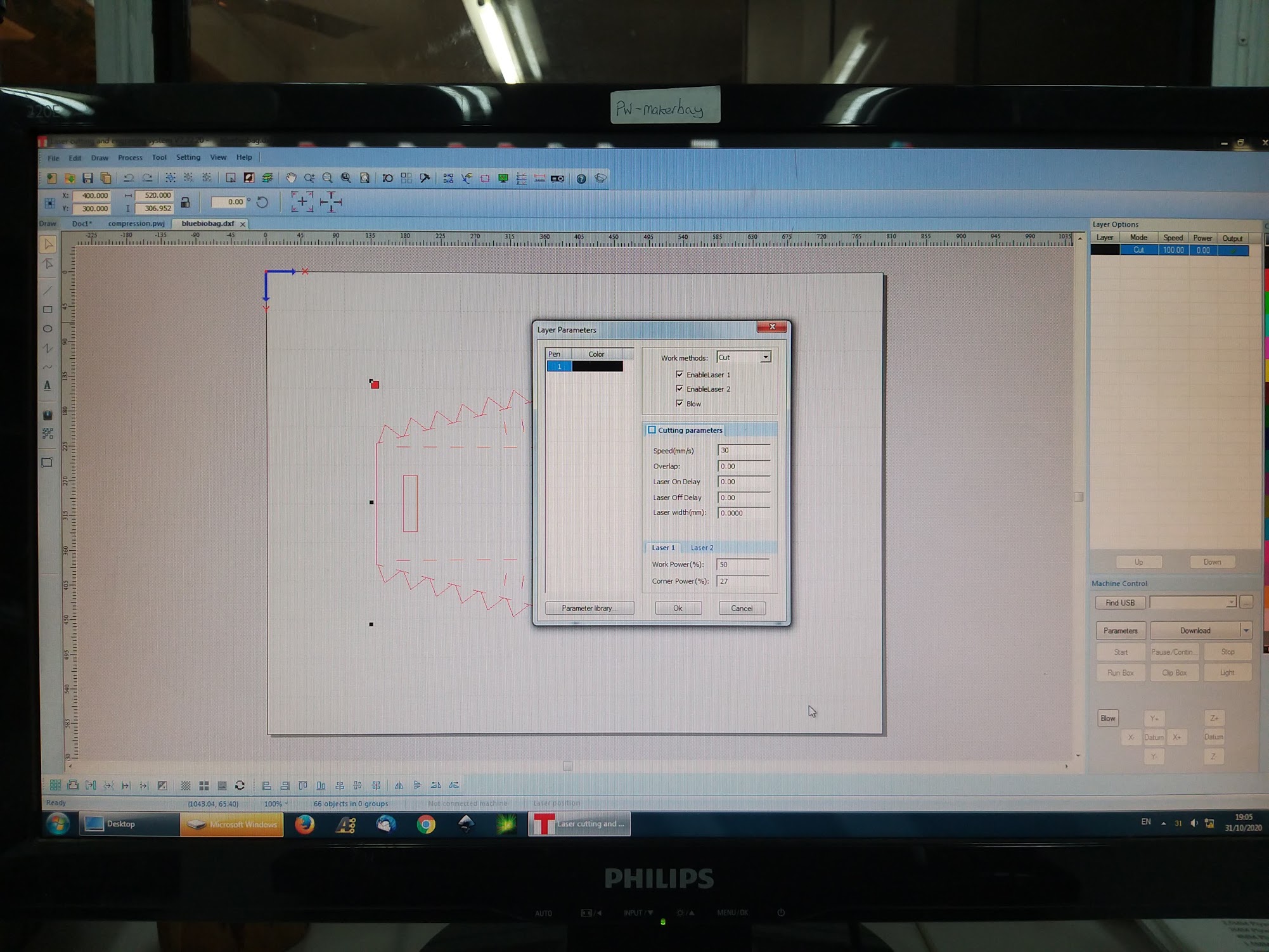

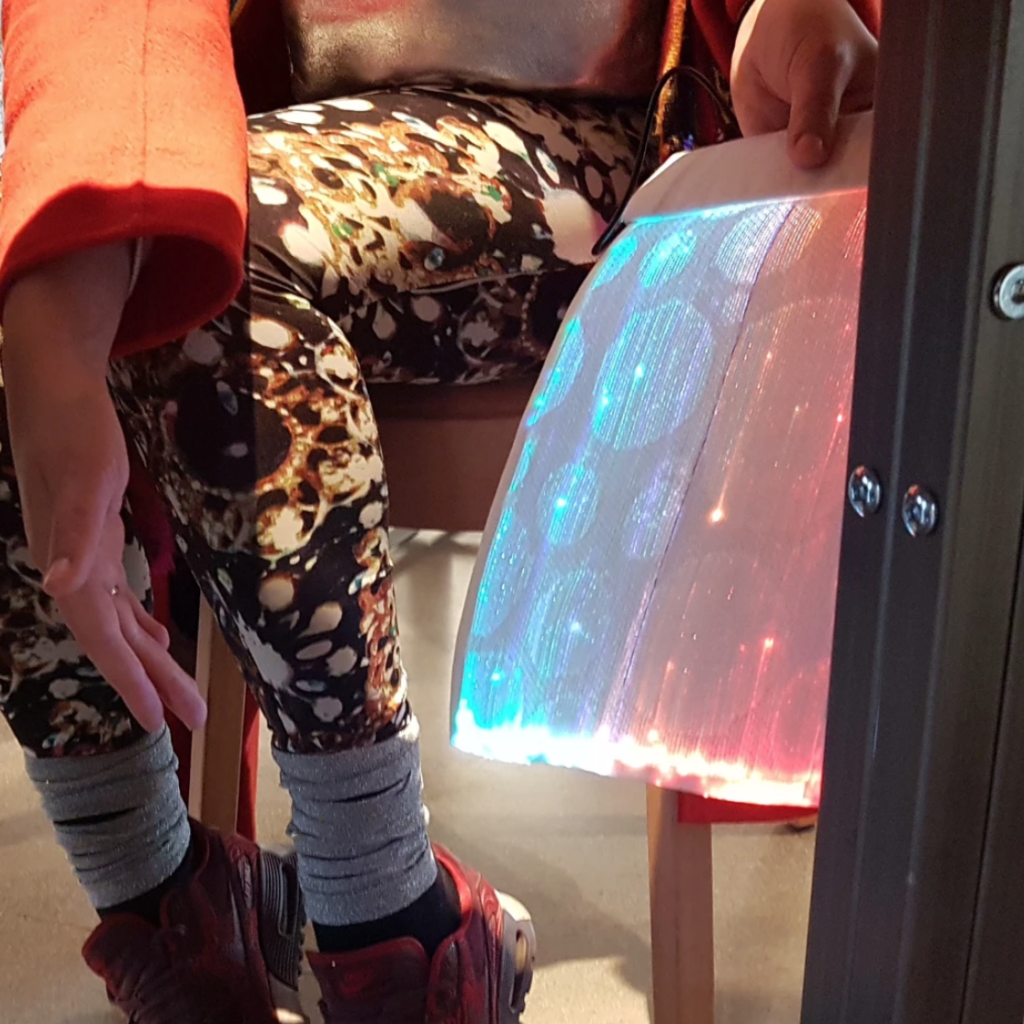

2. Laser-cut test

The result of the laser cutting test was quite good. It doesn’t require high power to cut it through. Here is the power, and speed I used in the laser machine parameter setup:

- Speed: 30mm/s

- Work Power: 50%

- Corner power: 27%

After conducting the property test, we found that there are many possible applications for gelatin-based bioplastics. It can be used as an alternative organic material to make bags, wallets, food packaging, fork and knives, clothes, etc.

In part 2, I will share how I turn the gelatin-based bioplastic sheet into a tote bag.

Responses